Humanoid robot maker Apptronik Inc. has inked a deal with Mercedes-Benz AG in which the German automaker will explore ways to use the robots in its manufacturing processes.

The agreement is part of Mercedes-Benz’ efforts to modernize its production network through technologies such as artificial intelligence (AI) and humanoid robots. With Austin, Texas-based Apptronik, the automaker said it is making a “low double-digit-million-euro” investment.

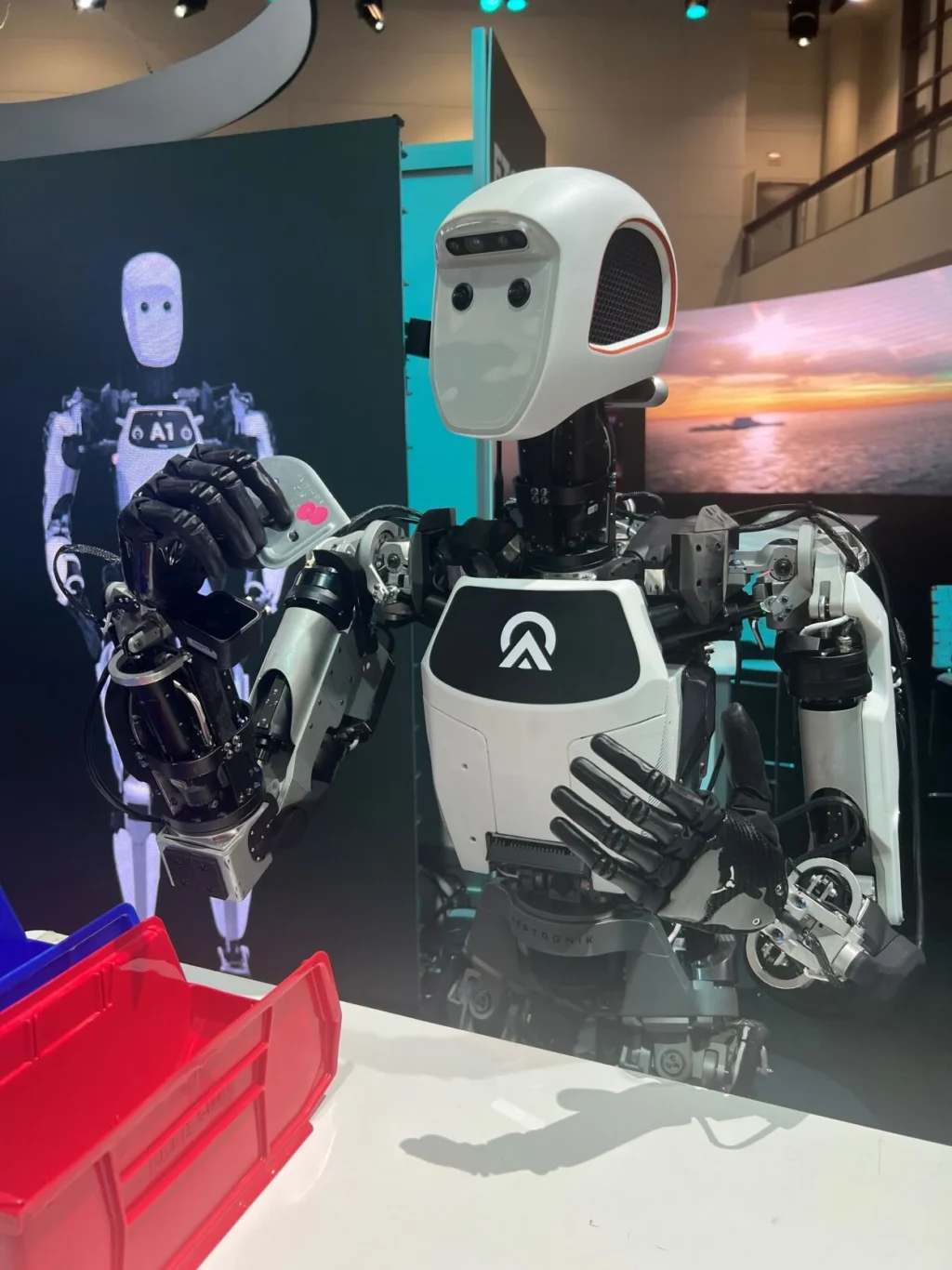

Attendees at the International Manufacturing Technology Show in September got an up-close view of one of Apptronik’s Apollo robots:

The Apollo robots have also been collecting production environment data for specific use cases in the automaker’s digital production eco system, according to Mercedes. Some of the data has been transferred by human production workers using teleoperation processes, meaning the robots are remotely controlled, as well as with augmented reality.

The automaker said the next step for the robots will be to perform autonomous operations. Much of the testing is being done at the company’s Digital Factory Campus in Berlin.

Other automakers are testing robot workers in production settings, too. BMW Group has used humanoid robots, known as Figure 02 (F.02) and supplied by California company Figure, to successfully insert sheet metal parts that were then assembled as part of a chassis during a trial run that lasted several weeks at BMW’s plant in Spartanburg, S.C. The purpose of the F.02 robots is to save human workers from doing ergonomically awkward and tiring tasks.

Content retrieved from: https://www.advancedmanufacturing.org/manufacturing-engineering/mercedes-invests-in-humanoid-manufacturing-robots/article_c58ca588-0d48-43aa-a0f9-80e9a896755c.html.